Customization

Customization technology

DAIKYO GIKEN-KOGYO’s salespeople are great partners for our customers. Our company’s original brand is named “IVY”. Just as the ivy plant can find its way into small spaces, we strive to be great partners for our customers by working together to fulfill ever-changing customer needs, no matter how small or niche, for everything from materials, adhesives, shapes, and packaging, to worksite equipment, and everything else required to complete a product.

Material

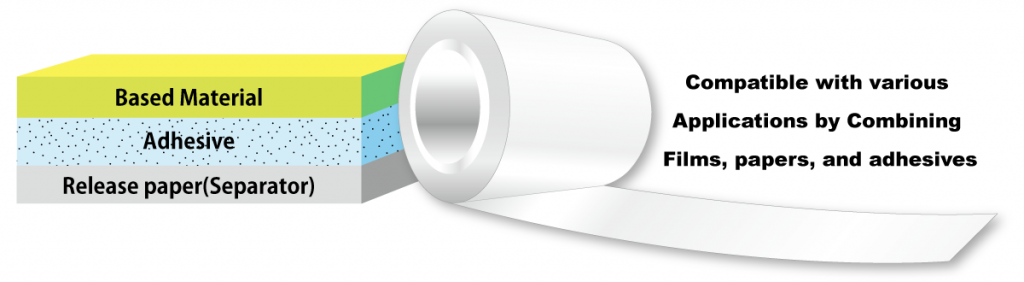

| Based Material |

|

|---|---|

| Adhesive*2 |

|

| Release Material |

|

It is also possible to give the based material adsorption performance.

It can be applied to one side of the base material to make a single-sided tape, and to both sides to make a double-sided tape.

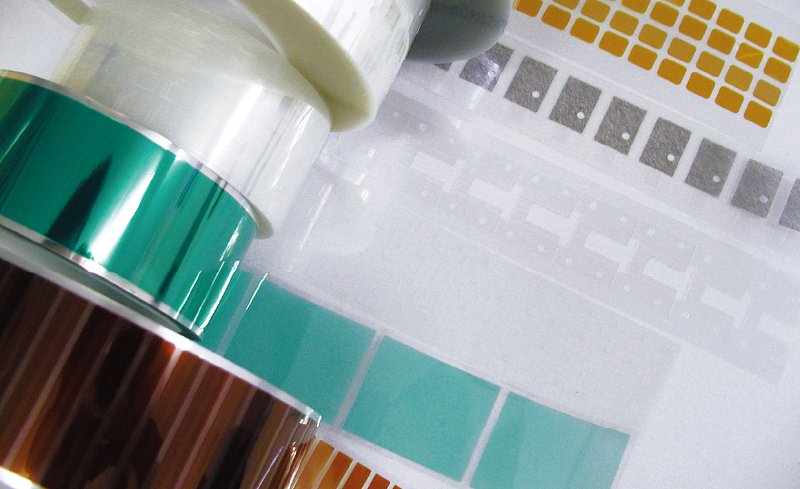

Processing technology

- Slitting

- Micro Slitting

- Rewind Slitting

- Sheet Cutting

- Laser Cutting

- Cutting Plotter Cutting

- Various Pressesting(Press/Rotary Machine)

- Laminateting

- Lamination Processting

- Folding

- Bobbin Winding

- Masker roll Production

- Adhesive Coating

- Various Printing

Others

- Assembly

- Inspection

- Equipment introduction consultation

Flow of customization

Minimum 1 month to maximum number of years until completion

Meeting

Discussion with Engineer or Designer

- Confirmation of custom request

- Confirmation of use

- Confirmation of on-site line

- Confirmation of the schedule

Confirmation of current product

- Product number, size, color, etc.

- Lot used

- Receive samples of actual product

Prototype Creation

Try and errer

Prototype Testing