Quality assurance

Daikyo Quality Mind

Let’s Fight! For Claim “Zero” / Defects “Zero”

It is a mindset that all Daikyo members must have.

It represents the hearts and spirits of Daikyo to achieve our ultimate goal :

Zero(0) Customer Claim Zero(0) Defect.

Daikyo Giken-Kogyo Group pursue a policy

All of the companies of the Daikyo Giken-Kogyo Group pursue a policy of “0 complaints and 0 defects” through DQM (Daikyo Quality Mind) activities, which include the establishment and rigid adherence to the following quality charter in order to continually realize our management philosophy.

- We will always provide products with quality and technology which exceed customer expectations.

- The foundations of quality improvement are each individual employee’s day-to-day operations, awareness, and proper work procedures.

- Company employees shall be aware that improving their own capabilities translates to improved product quality, and shall continually aspire to improve themselves.

- All relevant laws, regulations, and other rules of relevant countries shall be strictly adhered to at all times.

- Daikyo Giken-Kogyo employees shall work towards quality improvement with pride and enthusiasm.

Business content

In order to reliably provide the product quality required by customers, the Quality Assurance Department carries out a variety of activities including measures of various tape physical properties, high precision measurement of dimensions, creation of quality inspection tables which indicate product quality, and handling of inquiries related to environmental issues (RoHS regulations, REACH regulations, and other certifications of non-inclusion; chemSHERPA; etc.), and carries out its daily activities with the level of responsibility befitting the department responsible for overseeing quality. In addition, we believe that in the event of any claims or complaints, reliably and promptly investigating root causes and implementing permanent countermeasures are key to ensuring greater customer faith and trust.

List of measuring instruments

| Constant temperature and humidity chamber |  |

Temperature setting range: -40 to 150℃ Humidity setting range: 20 to 98% |

This device allows for programmed operation of heat shock and other environmental tests at set temperatures between -40 and 150℃. |

|---|---|---|---|

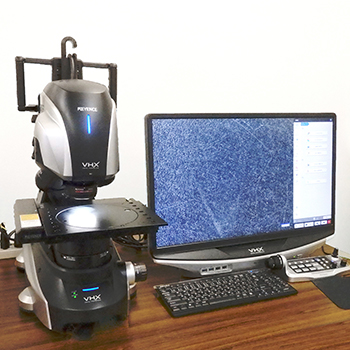

| VHX Digital Micro Scope (KEYENCE) |  |

CMOS images sensor – Pixel count: 3,190,000 pixels Object lens magnification: 20x to 6000x magnification Zoom lens magnification: 20x to 200x magnification Stage size: 150 mm × 150 mm |

This is a microscope with additional dimension measurement capabilities, which allows for measurement of depth direction while changing image integral processing and focus. Also allows for simple 3-dimensional measurement of dimensions and shape. |

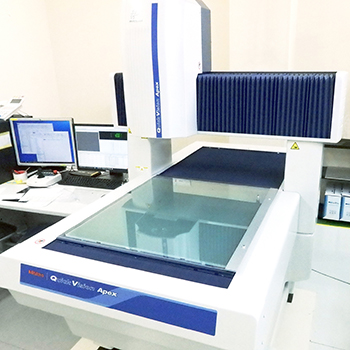

| 3D High Performance Vision Measuring System (Mitutoyo) |  |

Measurement range: 600 ×650 ×250 (X, Y, Z) mm Minimum display: 0.1 μm |

This system makes measurement of large scale products possible, allows for ring lighting illumination to be set within a range of 30° to 80°, and is well-suited to measurement of inclined surfaces and minute height variations. |

| Tensile tester (Minebea) |  |

Tension direction: 90°, 180° Maximum load: 200 N Measurement range: Adhesive force, peel force, shearing force |

This device allows for JIS Z 0237 compliant measurement and is capable of handling maximum loads of up to 200 N. |

| Holding force tester | Carries out measurement of deviation amount and fall time holding force using in-house developed jigs. | ||

| Gakushin tester | This device allows for assessment of the surface abrasion resistance of adhesive and base material surfaces using in-house developed jigs. | ||

| Viscosity measurement device |  |

This device is used to measure the viscosity of hot-melt, emulsion, and other adhesives developed by our company. | |

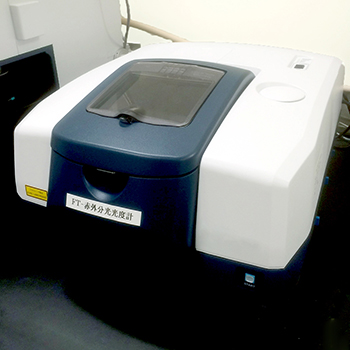

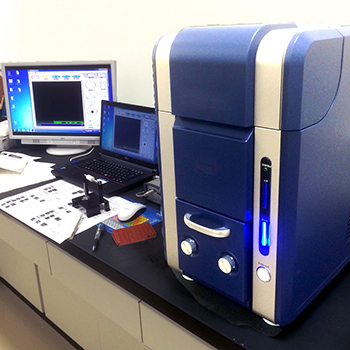

| Fourier-transform infrared spectroscope (FTIR) |  |

FTIR uses an interferometer to simultaneously detect all wavelengths without dispersion, and user Fourier transformation to calculate each wavelength component for detection and analysis. | |

| Scanning Electron Microscope (SEM) |  |

This device monitors subject objects by irradiating them with electron beams then detecting the internal electromotive force of the secondary electrons, reflected electrons, transmission electrons, X-rays, etc. emitted from the subject object. | |